Apart from the offshore work, HBK Oil and Gas Services Co are active onshore in the various Industrial Complexes. These includes QAPCO, QAFCO, QVC, Q-Chem, QASCO, NODCO, NGL, QP Dukhan, Ras Abu Fontas, QATARGAS, RASGAS, OXY and various other industrial establishments. Apart from the offshore work, HBK Oil and Gas Services Co are active onshore in the various Industrial Complexes. These includes QAPCO, QAFCO, QVC, Q-Chem, QASCO, NODCO, NGL, QP Dukhan, Ras Abu Fontas, QATARGAS, RASGAS, OXY and various other industrial establishments.

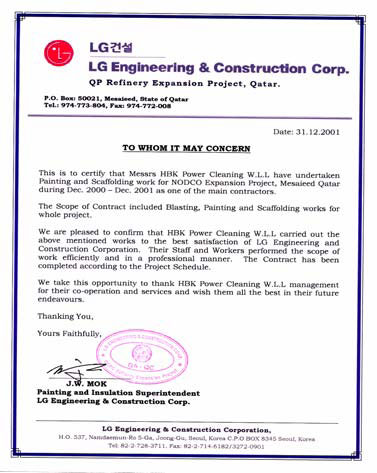

HBK Oil and Gas Co as major painting/scaffolding contractor and also as subcontractor to other multinational contractors have completed number of major contracts in Onshore. The works requires a high standard of safety, fundamental knowledge of the working environmental and total adherence to the Client schedule. HBK organisation has track record of completion of the work within time frame and in accordance with the specifications at all times. Longlist of satisfied Clients is an indication to our relenting endeavors to meet the organisation objectives and for customer satisfaction.

Highlight of our capabilities onshore is the established facilities in our yard located in salwa road which can handle surface preparation and painting of appropriate 1000M2 a day. Spacious scaffolding yard, blasting and painting facilities includes shaded area to protect from wind and humidity, Air conditioned chemical store, warehousing facility and has infrastructures like auto blast machine, recycling system, crane facility and full equipped garage. Highlight of our capabilities onshore is the established facilities in our yard located in salwa road which can handle surface preparation and painting of appropriate 1000M2 a day. Spacious scaffolding yard, blasting and painting facilities includes shaded area to protect from wind and humidity, Air conditioned chemical store, warehousing facility and has infrastructures like auto blast machine, recycling system, crane facility and full equipped garage.

Since inception in 1973 HBK Oil and Gas Co. had been pioneering in Off-shore as well as in On-shore operations as specialists in Protective Coatings with long line up of contracts over these years all concluded in a tidy manner conferring highest degree of customer satisfaction.

Ras Laffan Common Cooling Water System Project, considered one of the prestigious and challenging contracts so far in Qatar was awarded to CCIC in 2002 for construction and installation of carbon steel pipes for Qatar Petroleum. The scope of surface preparation and coating of external surface in contract was awarded to HBK Power Cleaning overriding stiff challenges even from International companies.

HBK Oil and Gas Co. stood up to the demanding situation of handling, surface preparation and coating of 8 – 12 pipes of about 3M diameter and 24 M long daily. Handling system, unique in its kind and innovative in design was built in record time fulfilling all safety requirements and was integrated with blast shop and paint shop. HBK Oil and Gas Co. stood up to the demanding situation of handling, surface preparation and coating of 8 – 12 pipes of about 3M diameter and 24 M long daily. Handling system, unique in its kind and innovative in design was built in record time fulfilling all safety requirements and was integrated with blast shop and paint shop.

The handling system with motorized trolleys on rails run through about 150 meters catering the receipt, movement through blast shop, paint shop and delivery of finished pipe efficiently and safely. Blast shop and paint shop sizing 15 X 54 M each are installed with state of art cyclonic dust extractors, abrasive recycling system and intrinsically safe lighting system.

The progress of the contract so far is amazing and is in tandem with quality and time frame set by the client. The obvious customer satisfaction was reflected in the award of a part of scope of different activity i.e. Blasting/application of Glass flake lining to the internal of piping at same project, being mainly done by an other subcontractor The progress of the contract so far is amazing and is in tandem with quality and time frame set by the client. The obvious customer satisfaction was reflected in the award of a part of scope of different activity i.e. Blasting/application of Glass flake lining to the internal of piping at same project, being mainly done by an other subcontractor

In addition to the Common Cooling Water System Project at Ras Laffan, we had been awarded the prestigious blasting and painting scope of QAFCO-4 Expansion Project by CCIC. The contract is progressing in phase with the contractual requirement in our yard in Doha and at Ummsaid simultaneously. |